Awci Technical Manual 12-b

AWCI 117, 2014 Edition, 2014 - Technical Manual 12-B; Standard Practice for the Testing and Inspection of Field Applied Thin Film Intumescent Fire-Resistive Materials; an Annotated Guide Provides field inspection procedures for the testing of thin-film intumescent fire-resistive materials. Provides field inspection procedures for the testing of thin-film intumescent fire-resistive materials. Includes testing criteria for thickness measurement of applied coatings.

AWCI TECHNICAL MANUAL 12-B PDF

Awci Technical Manual 12-b Download

AWCI Technical Manual B, “Standard Practice for the Testing and Inspection of. Field Applied Thin-Film Intumescent Fire-Resistive Materials. Provides field inspection procedures for the testing of thin-film intumescent fire- resistive materials. Includes testing criteria for thickness measurement of applied . AWCI Technical Manual B, Standard Practice for the Testing and Inspection of Field Applied Thin-Film Intumescent Fire-Resistive Materials; an Annotated.

| Author: | Dujinn Sat |

| Country: | Ukraine |

| Language: | English (Spanish) |

| Genre: | Love |

| Published (Last): | 22 March 2013 |

| Pages: | 370 |

| PDF File Size: | 6.51 Mb |

| ePub File Size: | 2.22 Mb |

| ISBN: | 783-2-36237-610-7 |

| Downloads: | 3567 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Gardajind |

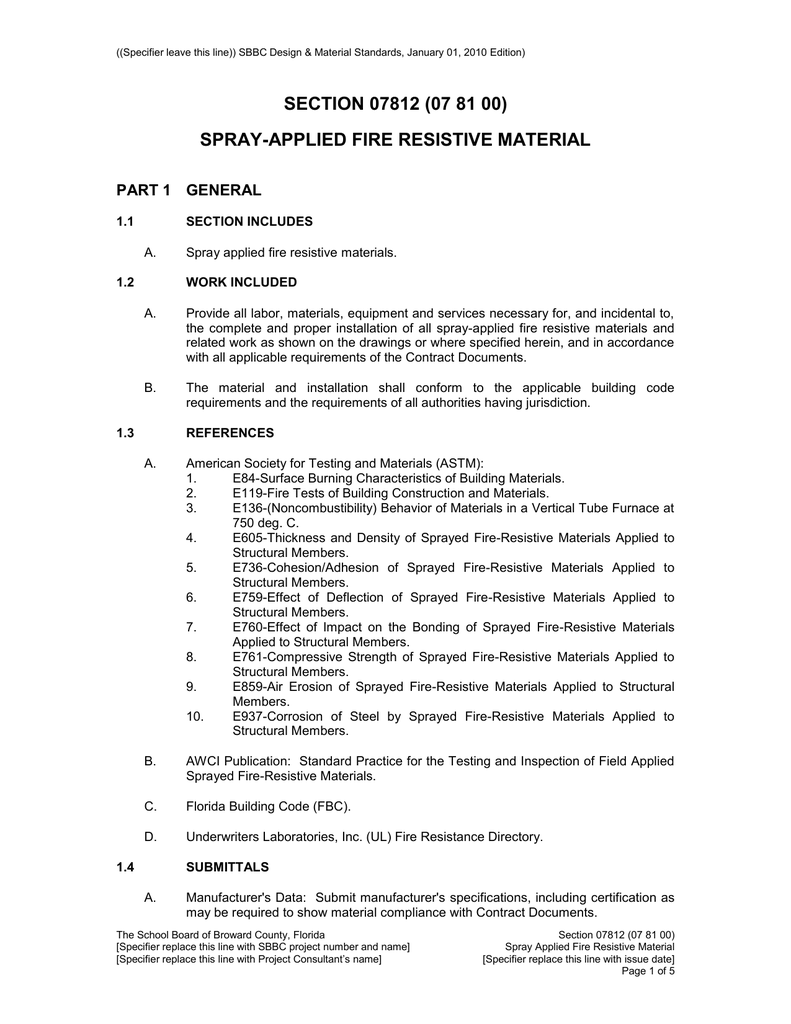

In-place fire protection material not in compliance with the specification requirements must be corrected prior to the application of the decorative top coat. If necessary for job schedule, the General Contractor shall provide enclosures and heat to maintain proper temperatures and humidity levels in the wwci areas.

Provide ventilation in areas to receive work of this section during application and minimum 24 trchnical after application. Before proceeding with the work, the installer will apply the primer, factory-manufactured architectural fire protection sections and decorative top coat to a representative substrate section of 10 square feet in size.

Technical Manual B

Patching must be performed by the qualified installer and applied in accordance with the manufacturer’s installation instructions. Do not proceed with remaining work until workmanship, color, and sheen are approved by Architect.

Send your questions to jones awci. Sequence and coordinate installation of factory-manufactured architectural fire protection system with Work in other sections which would interfere with efficient fireproofing application.

Once agreed upon in writing, it serves as a guide for the finished work. Thickness determinations shall be made at nine locations around the beam, at each end of a in. Company specializing in manufacturing the work of this section with a minimum of three years documented experience and certified by the material manufacturer.

Areas will be designated by the Architect. Do not commence installation of the factory manufactured architectural fire protection system until the contractor, installer and inspector have examined the surfaces to receive the fire protection and determined the surfaces are acceptable to receive the fire protection material.

The following is one example of how a mock-up on a large project might be specified. The fire protection material inspection manjal be performed prior to the application of the decorative top coat. At project closeout, provide to Owner or Owners Representative an executed copy of the manufacturer’s standard limited warranty against manufacturing defect, outlining its terms, conditions, and exclusions from coverage.

A stand-alone reading of section 6. What could have caused this, and how do we avoid it recurring? Submit applicator’s current certification as a manufacturer trained and approved installer.

AWCI’s Construction Dimensions – October 2013

All batch number, product identification and quantities shall be recorded on appropriate QC documents. Provide a mock-up for evaluation of surface preparation techniques and application workmanship.

Upon completion of installation, all excess material, overspray and debris must be cleared and removed from manhal job site. A concrete surface could be too slick because it has been coated with some kind of sealer, or tecjnical forms left a tight surface that was not roughed up or otherwise pretreated before the plaster was applied.

After several failed attempts to explain this testing procedure to me I first took it to mean one must measure near each end of the beam, 12 inches inthe technical sales rep wound up drawing a diagram that finally made it clear.

All surfaces to receive the factory-manufactured architectural fire protection material must be clean, dry and free of oil, grease, loose mill scale, dirt, dust or other foreign substances which would impair bond of the architectural fire protection material to the substrate.

Grind smooth all weld spatter and defects prior to commencement of fire protection installation. Information must demonstrate equivalence of product and performance to the specified material and complete systems. Jones is AWCI’s director of technical services. Include evidence that the fire testing was sponsored by the manufacturer and that the material tested was produced at the manufacturers facility under the supervision of third party certification personnel.

Factory manufactured architectural fire protection system will be a complete system from a single source consisting of primer, factory manufactured fire protection sections, section adhesive, edge sealant and decorative topcoat. Structural steel and framing with reference to primer receiving fire protection materials. Submit manufacturer’s written installation instructions.

Interchar can provide fully fire proofed steelwork without the need to topcoat. That’s where reading the earlier material comes in handy. Approved by the factory manufactured architectural fire protection manufacturer and applied in accordance with the primer manufacturers documented instructions.

Verify that all clip hangers, piping, ducts, equipment or other items which would interfere with the installation of the factory-manufactured architectural fire protection system are not positioned or installed until installation is complete.

To ensure a concrete surface is clean and rough enough to receive a stucco finish, it may need to be sandblasted or mechanically abraded, a dash coat of the cement plaster mix can be applied before the finish coat, or metal lath can be attached using poweractuated fasteners implying a two- or threecoat stucco system to follow.

Most Related

Awci Technical Manual 12-b 3rd Edition

Due to the COVID-19 pandemic, disruptions to the shipping chain may occur and your order delivery may be delayed. We apologize for the inconvenience. Field-Applied Sprayed Fire-Resistive MaterialsDouble Pack -Technical Manual 12-A, 4th Edition; and Technical Manual 12-B, Third Edition Technical Manual 12-A, 4th Edition; Standard Practice for the Testing and Inspection of Field Applied Sprayed Fire-Resistive Materials; an Annotated Guide |